Our philosophy

C.B.S Readytex, the company you need for your ecological garment

Our Philosophy

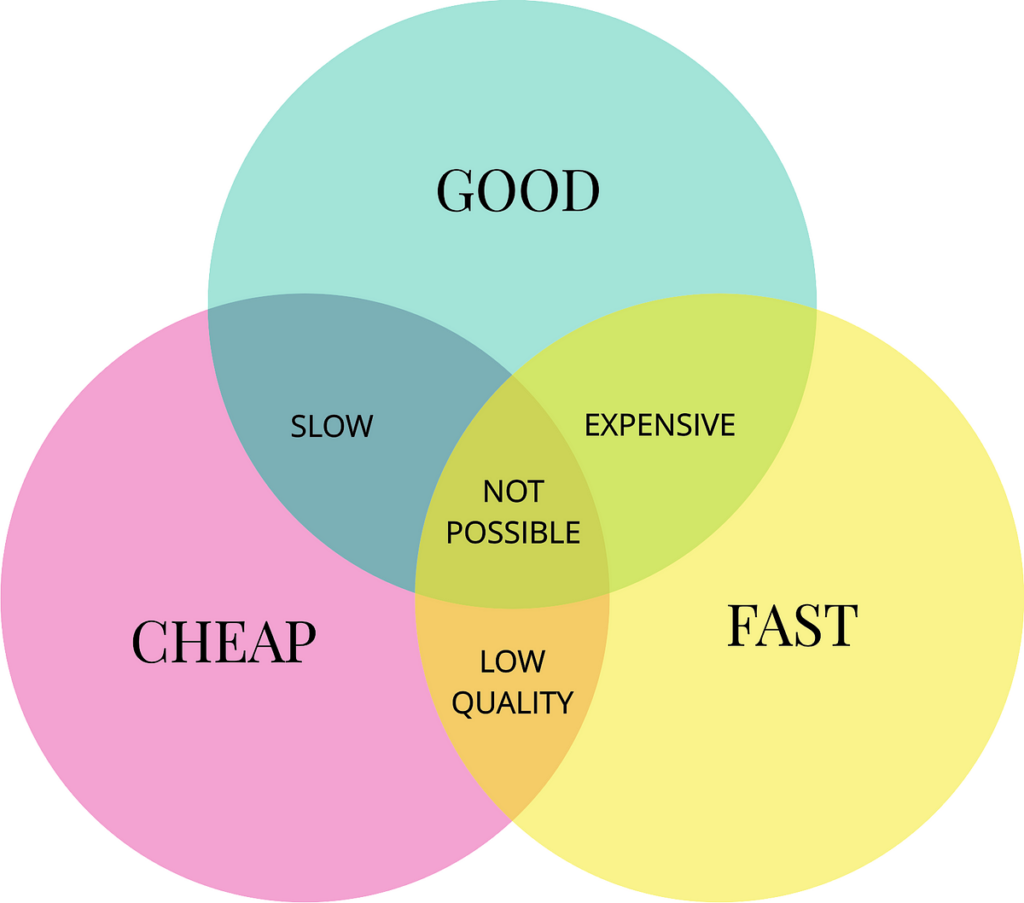

We make clothes in a socially, environmentally, and ethically responsible way. Our activities are based on and driven by our understanding that we have to do our part to protect the fragile environmental balance of our planet. At the same time we are a small company that has the ability to know all its partners and have strong and lasting collaborations with manufactures and suppliers.

In the light of recent scandals in the garment industry, we believe transparency is very important. All our suppliers are committed to our Code of Conduct and fulfill the criteria set out by GOTS.

It is with pride that we do not outsource our productions and that everything is made within a 200Km radius from our unit. This minimizes CO2 emissions but is also an investment in the local economy. Our products can carry the made in EU label which ensures fair conditions and no child labor.

We strive to improve local working conditions, in all parts of the supply chain. Abiding with merely being above the minimal wage is not enough for us we want more than just a living wage and good labor conditions in the factories where fabric is made into clothing. Since this is on our hands we make sure our workers are paid well and are treated fairly while being in a safe environment.

Founding the Legacy

Great Grandfather Dimitrios Litsas was an early 1900 trader and manufacturer of maypole ribbons used for dancing during festivals, with exports mainly to Egypt and Romania. He was based in Izmir, Asia minor in Turkey.

Expanding Horizons

Grand Father Konstantinos Litsas in 1922 owned a knitting garment unit and a shop for essential home fabrics called ELLINIS in Thessaloniki Greece

Modernization and Sustainability

Father Dimitrios Litsas in 1974 founded the export company “Readytex” ready to wear clothes and a buying agency. He manufactured garments from circular knitting machines. With sales all over Europe.

Diversification Era

1994 transferred to self owned facilities 2585m3 State of the art production and export unit with a capacity in the range of 20,000-30,000pcs per month. Administration, Design, Sewing, Cutting, Ironing, Labeling, Packing, Storage all done in house.

Digital Evolution

2009 one of the first companies in Greece to get GOTS certified. Dimitrios Litsas a visionary that started in a niche market as he just knew that environmentally friendly, organic, recyclable, clothes and sustainability would become a requirement to modern consumers.

Example Title

Daughter Despina Litsa becomes full time CEO in 2017 which is now called “C.B.S” Clothing Business Services. Fresh ideas, a background in Molecular biology promoting environmental preservation, supported by social responsibility and a commitment to ethical working conditions.

Example Title

Future Innovation and reliability in the fashion industry. Strategic alliances /short-time delivery and maintenance of the highest quality standards. Enhancing, modernizing and improving our equipment and production processes and implementing new business models that transform the traditional linear structure to new sustainable and circular methods.

We at C.B.S realize that our claims need to be substantiated with evidence. The proof of our commitment to a truly ecological production lies in our certified-organic garments.

C.B.S Readytex has been in cooperation with the Association for the Assessment of Environmentally Friendly Textiles (Oeko-Tex International) and uses the Oeko-Tex 100 Standard to evaluate and screen for any harmful substances present within processed textiles.

ENVIRONMENTAL AWARENESS

Cotton is a vital commodity and provides a large financial income for the textile industry worldwide. However the conventional cultivation of cotton has a leads to massive environmental and health problems. The World Health Organization estimates that while conventional cotton farming uses only 3% of total farmland, it consumes 10% of chemical pesticides and 22% of all insecticides. Farmers have been tempted to use high concentrations of chemicals in the hope of higher yield and income. This thoughtless usage of fertilizers and pesticides has led to poisoned farmlands and water supplies. Furthermore, it has led to pests that develop resistance to these chemicals and this has as a consequence the usage of higher quantities of these increasingly toxic products.

Organic methods of cotton cultivation produce healthy plants without polluting the soil and the surroundings. It is grown with natural fertilizers and is free from toxic chemicals. Organic farming allows the soil to replenish and maintain its fertility naturally. Mechanical cultivation and botanical or biological means are used to control pests and weeds. The entire process consumes less fuel and energy and emits fewer greenhouse gases.

The organic cotton we use in our ecological concept has been grown in organic cotton farms where no pesticides or other chemicals are used. Only natural fertilizers such as manure and compost. Furthermore, the cotton production process is followed from start to finish, from the grain to the finished product. This means less exposure for the people growing it and less chemicals in the environment, which overcomes reduced soil fertility, salinization (increasing salt concentration in the soil), and loss of biodiversity.

Recycling cotton is a sustainable alternative to conventional methods because it means that unwanted unused material will be reborn into a high-quality garment increasing its life span. Way too much of what is made these days ends up in the trash at the end of its useful life. Recycled natural fibers are spun into yarn that can be used to make new fabrics. This minimizes the harmful environmental impact of each stage of production. It is difficult to quantify all the benefits from recycling garments but we try to point out a few.

- Even if originally pesticides were used to produce this cotton now we already have this material so instead of throwing it away we re use it so we get double its worth.

- The water and energy consumption is reduced as we do not need to use newly grown cotton. This is of great importance as there is a global water shortage. We also minimize the carbon footprint of the procedure.

- The dyeing processes changes when you use recycled yarns and fabrics. You use only 50% of the original water and no toxic or harmful chemicals.

ENVIRONMENTAL AWARENESS

In the production of eco-clothes no harmful chemicals which can cause long-term damage to peoples’ health and the environment are used.

All materials used in the dyeing and printing of the fabrics are ecologically friendly, while the dyes do not contain chemical substances that are harmful when in contact with the skin or the environment. Flatness of colors is achieved with high temperature washing with the addition of Marseille soap to deionized water. Bleaching is performed with the use of a liquid called peridrol (hyper oxide H2O2). It is a 100% natural process that uses the qualities of oxygen to bleach the fabrics.

Although we only use dyes that are free from harmful textile chemicals we carry out stringent laboratory tests (as confirmed by the OEKO- tex standard) for traces of any dangerous substances such as: Formaldehyde, Pentachlorophenol, PCP, AZO dyestuffs heavy metals (arsenic, lead, mercury, zinc, chromium copper a.o).In order to ensure our products meet standards and have accurate test and analysis data to support their green claims we have our production process certified. Although it is possible to certify the finished product itself at any time for quality assurance purposes we perform tests at each stage of production both at the raw material and the subsequent yarn and knitting procedure as well as the dyeing and printing process.

As we are conscious of the fact that the manufacturing of clothes has an impact on the soil and on water pollution from finishing processes, we try to accommodate the manufacturing process. All the waste produced by the dyeing process is treated through special cleaning filters that retain any harmful substances. We ensure that effluent from the dyeing process is handled responsibly before it is released into the environment. Waste is disposed of in the appropriate environmentally friendly ways. This is done by meeting the EU quality requirements, ensuring management of water, fertilizers, pesticides etc.

Safe choice

We have a long tradition and experience in the field of manufacturing clothes with a limited harmful effect on the environment.